The copper aluminum composite produced by pure physical process is a kind of conductive material with stable performance, high conductivity, not easy to fracture, not easy to layer, low resistance, strong oxidation resistance, electric corrosion resistance, easy molding and processing and stable output performance. It is not affected by the use environment, the composite surface will not fracture, but it can achieve excellent conductivity without reinforcement measures

Chalco aluminum's Cu al bimetal sheet is widely used in high and low voltage electrical appliances, electronic components, high and low voltage power transmission and transformation accessories, electrical accessories, power fittings and other industries, as well as traditional copper plate decoration industries such as copper door, copper mural, copper technology, copper decorative plate and copper ceiling. It has been tested, inspected, installed and used by many listed enterprises and national key projects, It has been affirmed by our customers.

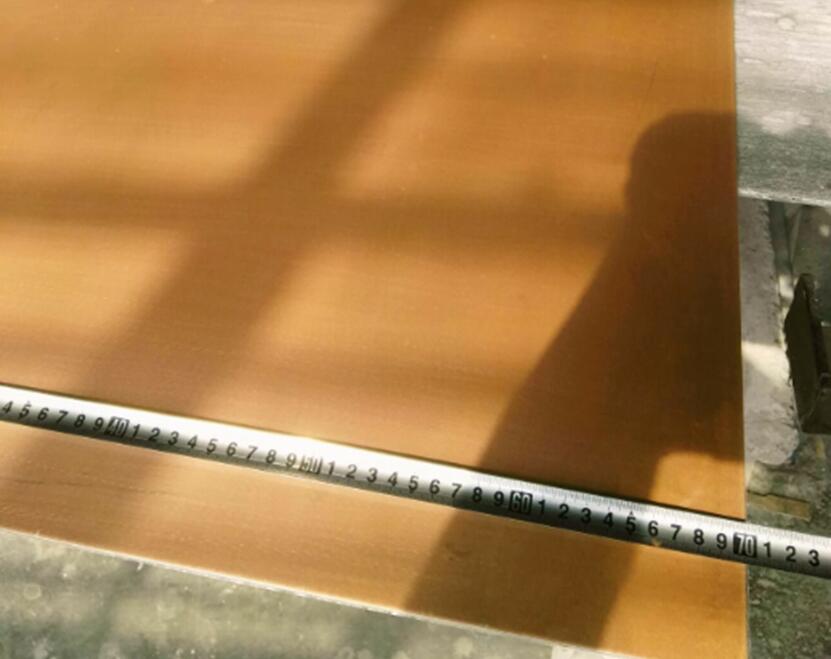

The Cu al bimetal sheet manufactured by Chalco aluminum physical and molecular fusion process is cold punched at room temperature. The composite has excellent extensibility, and there are no cracks, folds, peeling, delamination and falling off at copper, aluminum and their composite interfaces. Especially for the power fittings industry, it is used for the production of copper aluminum composite and copper aluminum transition equipment clamps. Fast forming, reliable electrical performance, strong oxidation resistance, electrical corrosion resistance and chemical reaction resistance.

It can also match the material thickness according to customer needs, which can ensure the processing of cold stamping, 90 ° bending, U-bend, square hole, round hole and special-shaped hole.