The current commonly used conductive materials in the power and electrical industry are copper and aluminum, and it is also the most commonly used heat exchange material in the world. The instantaneous heat absorption capacity of copper is 1.6 times faster than that of aluminum alloy, but the heat dissipation speed is slow, and the heat dissipation speed of aluminum alloy is 2.33 times faster than copper. However, copper is easily oxidized in an environment higher than room temperature, especially in an environment containing corrosive gases such as H2S, SO2, etc., copper is easily corroded. Therefore, aluminum bars are often used instead of copper bars in harsh environments. If the advantages of the two metal materials are combined, it will be a perfect conductive and heat exchange material. Therefore, whether it is used for conduction or heat exchange, aluminum copper bi metal sheet is an excellent choice. Aluminum-based outer layer composite copper is suitable for conductive bars and wires whose power supply frequency is higher than power frequency. Copper-based outer layer composite aluminum is suitable for electrical and thermal conduction in corrosive environments. Copper-aluminum hybrid composite is suitable for occasions where the conductivity is required to be greater than aluminum but less than copper.

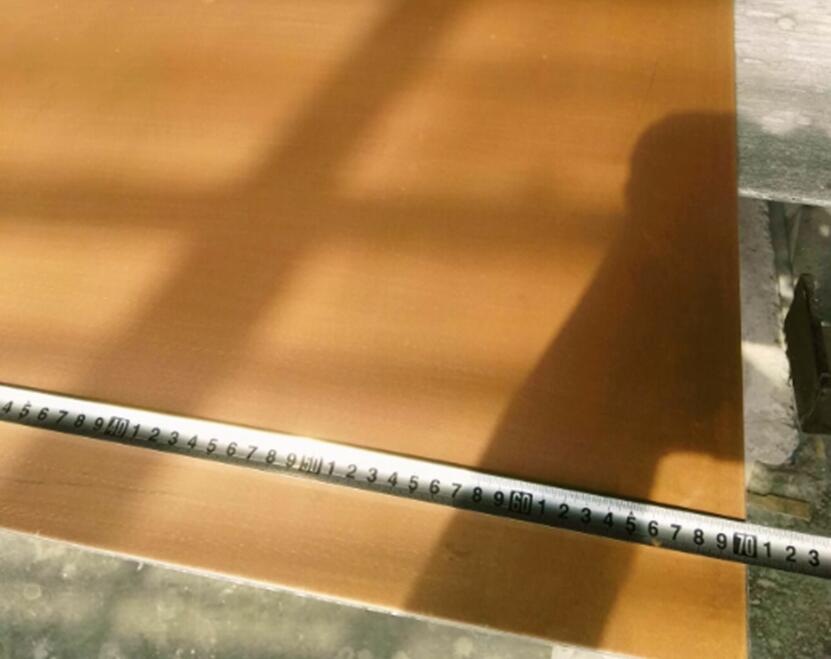

At the same time, copper-aluminum is directly composited with high sheet strength and good surface flatness. It has obvious cost advantages over copper veneer. It can be used for metal roofs, ceilings, copper doors and windows, kitchenware manufacturing and interior and exterior wall decoration. Customers can also color and press patterns on the board to increase the color.