Firstly, in terms of conductivity, compared with other conductor materials, this composite conductor material has low requirements for external intervention, good conductive effect and good comparative advantages. Secondly, it is light in weight. Compared with the traditional metal conductor, the mass of the traditional metal conductor copper is twice that of the composite conductor, which can provide greater efficiency for high-tech fields with high quality requirements. At present, it has been widely used in aerospace, rail transit and microelectronics, It can greatly improve the use efficiency of materials and improve the cost performance. Finally, from the perspective of economic cost, aluminum and copper as the most common conductor material in the market, especially the price of aluminum raw material is relatively cheap, which can greatly reduce the manufacturing cost of the composite conductor, which is also an important reason for the broad market prospect of copper aluminum composite conductor.

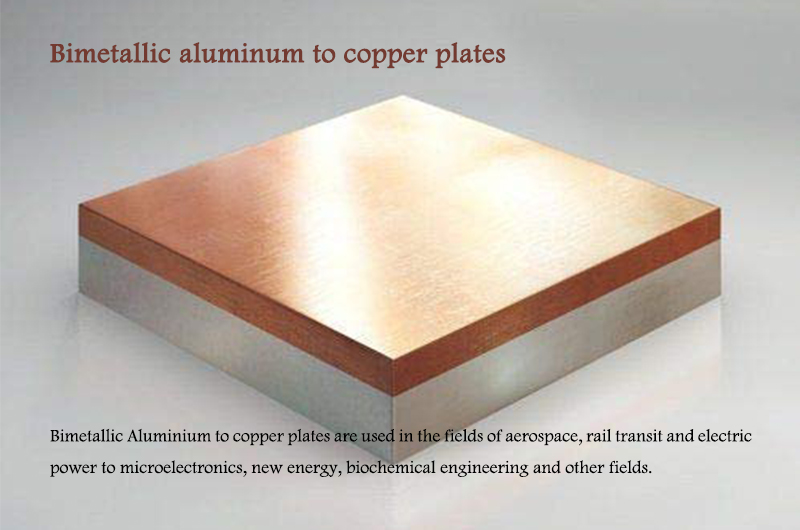

Bimetallic aluminum to copper plates is a conductor material with large section and carrying large current. It has high requirements for its service performance and reliability, and the production equipment and process are also complex.

With the continuous strengthening of the application and experiment of copper aluminum composite conductor in China, bimetallic aluminum to copper plates will expand in more and more fields, gradually from aerospace, rail transit and electric power to more and more new fields such as microelectronics, new energy and biochemical engineering. Represented by the automobile industry, many joint venture automobile manufacturing enterprises or domestic automobile manufacturing enterprises in China have begun to increase investment in R & D of production materials and processes. Many automobile manufacturing enterprises have taken copper aluminum composite conductor materials as an important research project for material use. With more and more investment in scientific research, especially the national attention to material technology, the application and manufacturing process of copper aluminum composite conductor will be more optimized. The production cost of bimetallic aluminum to copper plates will be continuously reduced, and the production quality and stability will be more fully guaranteed, which is more conducive to the performance of new composite conductor materials.